* With the introduction of jet airliners in the 1950s, several European aircraft manufacturers decided to build jetliners for the short-haul market. The most significant of these efforts were the British "BAC One-Eleven" and the Dutch "Fokker F28 Fellowship" -- along with the F28's successors, the "Fokker 100" and "Fokker 70". This document provides a history and description of the BAC One-Eleven and the Fokker Fellowship series -- as well as the unsuccessful German "VFW 614" and French "Dassault Mercure" jetliners.

* In 1956, British European Airways (BEA) issued a request for a short-haul jetliner to complement BEA's existing turboprop fleet, the model for the new jetliner being clearly based on the French Sud Aviation Caravelle. All major British aircraft firms responded with proposals. Hunting Aircraft proposed a 30-seat jetliner, the "Hunting 107" -- though nothing material was done with the concept before Hunting merged with Vickers-Armstrong, Bristol, and English Electric in 1960 to form the British Aircraft Company (BAC).

BAC officials sorted through all the concept designs that had been in progress at the ancestral firms to see which should be pursued further. The Hunting 107 seemed promising, but it was seen as too small, the design accordingly evolving into the 59-seat "BAC 107", to be powered by twin Bristol Siddeley BS75 low-bypass turbofans with 31 kN (3,175 kgp / 7,000 lbf) thrust each. Market studies showed that the BAC 107 was still too small, so in 1961 the design was further tweaked into the "BAC 111", with 80 seats and twin Rolls-Royce (RR) Spey low-bypass turbofans for powerplants.

The design becoming firm for development, the aircraft ended up having a low wing and a tee tail, with the Speys mounted in nacelles on each side of the tail. The designation was recast into the "BAC One-Eleven" when the project was publicly unveiled in May 1961, with several airlines in the UK and the US placing advance orders as a result. BAC officials forecast total orders of 400 machines.

The prototype was rolled out in the summer of 1963, with the aircraft performing its first flight on 20 August 1963, being painted in the colors of the launch customer, British United Airways (BUA). It flew a year ahead of the competing American Douglas DC-9, giving BAC a potential lead in the race for short-haul jetliners -- but the program suffered a setback on 22 October 1963 when the prototype crashed, all seven hands being lost, including well-known test pilot Mike Lithgow. The problem was due to the aerodynamic "blanking" of the tee tailplane by the wing and the engine nacelles at high angles of attack, with the aircrew then being unable to get the nose back down and the aircraft pitching up on its tail as a result. Aerodynamic changes and a "stick shaker" to provide stall warning to the aircrew were added as fixes.

The tragedy did not delay the program very much; accidents can happen in testing, and customer orders continued to roll in. Initial delivery of the production "BAC One-Eleven Series 200", to BUA, on 22 January 1965, this variant being powered by Spey Mark 506 engines with 46.3 kN (4,720 kgp / 10,410 lbf) thrust each. Several dozen such aircraft had been delivered by the end of 1965, with a total of 56 Series 200 machines built in all.

* As it emerged, the BAC One-Eleven Series 200 was made generally of aircraft aluminum alloy, with all-swept flight surfaces, tricycle landing gear, and twin RR Spey 25 Mark 506 turbofans with 46 kN (4,685 kgp / 10,330 lbf) thrust each, one on each side of the tail. The wing had a sweepback of 20 degrees at quarter-chord, with a wing fence about a third of the way from the fuselage. Each wing featured three-section Fowler flaps inboard of the aileron; wing de-icing was performed with engine bleed air. The tee tail had conventional rudder and elevators, though the tailplane was variable-incidence, mating to the tailfin via a bullet fairing.

All landing gear had twin wheels, the nose gear retracting forward, the main gear retracting from the wings inward into the fuselage. All fuel storage was in the wings, though center section fuel tanks were available as an option. There was an AiResearch auxiliary power unit (APU) turbine engine in the tail, with a distinctive upturned exhaust at the tip, for engine starting and ground power. The BAC One-Eleven was supposed to be able to fly from small airports where ground facilities were minimal, and also land and take off rapidly during journeys with multiple stops. The APU was run during take-offs to support cabin air conditioning, reducing the drain on thrust from diversion of engine bleed air.

___________________________________________________________________

BAC ONE-ELEVEN SERIES 200:

___________________________________________________________________

wingspan:

26.97 meters (88 feet 6 inches)

wing area:

93.18 sq_meters (1,003 sq_feet)

length:

28.5 meters (93 feet 6 inches)

height:

7.47 meters (24 feet 6 inches)

empty weight:

21,050 kilograms (46,405 pounds)

MTO weight:

35,610 kilograms (78,520 pounds)

max cruise speed:

850 KPH (525 MPH / 460 KT)

max cruise altitude:

10,670 meters (30,000 feet)

range:

1,870 kilometers (1,160 MI / 1,010 NMI)

___________________________________________________________________

There were two crew, not counting cabin attendants. Avionics were typical for the era -- radios, cabin intercom, radio navigation and landing systems, IFF transponder, weather radar, and autopilot. Maximum passenger accommodation was 89 seats in a "sardine can" configuration, seats being five across, though that was severe. Different mixed-class layouts could be accommodated using a moveable partition; a typical arrangement was 16 first-class seats in a four-across layout forward, and 49 seats in a five-across layout in the rear, for a total of 55 seats. There was a galley forward and a toilet aft.

Passenger windows were of oval configuration. There was a passenger door on the left forward side of the fuselage, with a matching service door on the right, as well as an "airstair" passenger loading door under the tail. The forward passenger door also had an airstair that could be hydraulically extended; it apparently wasn't fitted to early production, and may have not been fitted to all later aircraft. There was an emergency exit over each wing, plus an under-floor baggage hold fore and aft of the wings, with the doors on the right side of the aircraft. Of course, the cabin was pressurized and climate-conditioned.

BACK_TO_TOP* The Series 200 was followed by the "Series 300", much the same but geared for higher take-off weight and longer range, with uprated Spey Mark 511 turbofans providing 51 kN (5,170 kgp / 11,400 lbf) thrust each, a wing center-section tank, plus airframe and landing gear reinforcement. Accommodations were as those for the Series 200, except for two toilets in the rear instead of one. Only nine Series 300 machines were built, but a total of 69 "Series 400" machines were produced for the US market, being identical to the Series 300 except for Americanized avionics, and two spoilers for lift-dumping on each wing. Both the Series 300 and Series 400 flew in 1965.

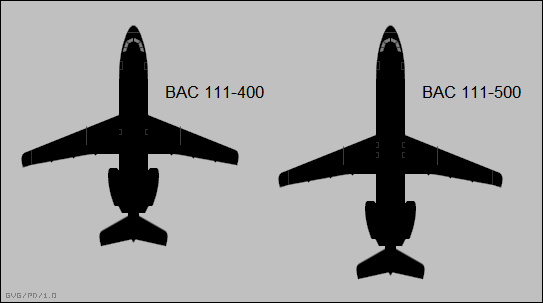

The larger "BAC One-Eleven Series 500" AKA "Super One-Eleven" was introduced in 1967, this variant featuring a fuselage extension of 2.54 meters (8 feet 4 inches) ahead of the wing and of 1.57 meters (5 feet 2 inches) behind it, giving a total length of 32.72 meters (107 feet 4 inches) and a maximum passenger capacity of 109 seats. Wingspan was also stretched by 1.52 meters (5 feet), for a wingspan of 28.5 meters (93 feet 6 inches) -- the wingtip extensions had a sharper sweep on the rear than the rest of the wing, giving them a clearly "tacked-on" appearance. Empty weight increased by about 12%, with the powerplants being accordingly changed to uprated Mark 512 Spey turbofans, with 55.8 kN (5,670 kgp / 12,500 lbf) thrust each.

Aside from the larger capacity and two emergency exits over each wing instead of one, accommodations on the Series 500 were similar to those of the Series 300/400. The Series 500 sold well, with 86 produced. That total included a custom variant for British European Airways (BEA), the "510ED", with the cockpit controls rearranged for commonality with BEA's Hawker Siddeley Trident jetliners.

* As the 1960s went on, the One-Eleven came under increasing pressure from the Douglas DC-9, then the Boeing 737 and the Fokker F28 Fellowship. In response to the F28, BAC developed the "Series 475", introduced in 1970, with the original fuselage length of the Series 400 but the larger wing and uprated engines of the Series 500, along with landing gear with low-pressure tires for rough field operation. The Series 475 was intended for "hot and high" operation; only ten were sold.

Three of the Series 475 machines, obtained by the Omani air force, had a "quick-change" passenger-cargo interior and a tip-up cargo-loading door on the front left side of the fuselage, 3.05 meters wide and 1.85 meters tall (10 feet x 6 feet 1 inches). While sources mention a "BAC One-Eleven Freighter" variant of such configuration, it is unclear if any others were sold besides the Omani batch, though there are hints of aftermarket conversions.

A number of Series 200 and Series 400 machines were sold in executive / VIP configurations, military services being among the purchasers of Series 400 VIP transports, including two such for the Royal Australian Air Force and another two for the FAB, the Brazilian Air Force. A "hushkit" was developed to reduce engine noise by half, the main feature of which was a muffled exhaust extension, with a number of BAC One-Elevens updated accordingly.

Sales of the BAC One-Eleven were sluggish through the 1970s. A refined derivative of the Series 475, the Series 670, with quieter engines and other tweaks for the Japanese market, was flown as a conversion in 1977, but didn't go into production. BAC planned to introduce a "Series 700" with 134 seats and modernized Spey engines, but the project collapsed when Rolls-Royce went into bankruptcy and the new engines didn't materialize. In 1977, BAC merged with Hawker Siddeley to form British Aerospace (BAE), with "One-Eleven 800" then proposed with a fuselage stretched to 43.28 meters (142 feet), wingspan extended to 31.55 meters (103 feet 6 inches), CFM56 engines, and a passenger capacity of 150 seats in a mixed-class layout. That proposal went nowhere as well.

A deal was struck for license production of the One-Eleven by the Romanian government, but only nine "Series 560" machines, essentially Series 500s, were built by the "ROMBAC" collaboration through the 1980s -- sources are actually very mixed on this issue, some citing twice as many aircraft produced, but that may have been working off projections that didn't come true. The program bogged down and ultimately disappeared in 1989, when the decrepit Communist government of Romania finally collapsed. One Series 400 was fitted with more modern Rolls-Royce Tay turbofans by a third party to perform test flights in 1989, but nothing came of the exercise.

* A total of 244 BAC One-Elevens was built in all, the type serving with dozens of airlines worldwide -- notably BEA, Dan Air, and British Caledonian in the UK; a number of operators in the Far East and Africa; plus American, Aloha, and Braniff in the USA, US operators buying more than half the total. The sales were good enough to make the One-Eleven profitable, but it still failed to hold its own against strong competition from the DC-9 and 737. Most One-Elevens were withdrawn from service in the 1990s, the main problem being their noise levels had become unacceptable, though the type still lingered into the next century.

At last notice, Northrop Grumman was still flying one as an avionics testbed -- this aircraft having been used to support the Lockheed Martin F-35 Joint Strike Fighter program, the airliner being fitted with F-35 radar and defensive countermeasures.

BACK_TO_TOP* In the early 1960s, the Fokker company of the Netherlands began consideration of their own twinjet short-haul jetliner, as a progression from the company's popular F27 Friendship twin-turboprop airliner. The new jetliner was to have 50 seats, a range of 1,650 kilometers (1,025 miles), and twin Bristol Siddeley BS.75 turbofans. The initial concept was seen as too small, being expanded to up to 65 seats, powerplants being similarly upscaled to Rolls-Royce Spey Junior turbofans, the aircraft being publicly announced in 1962 as the "F28 Fellowship".

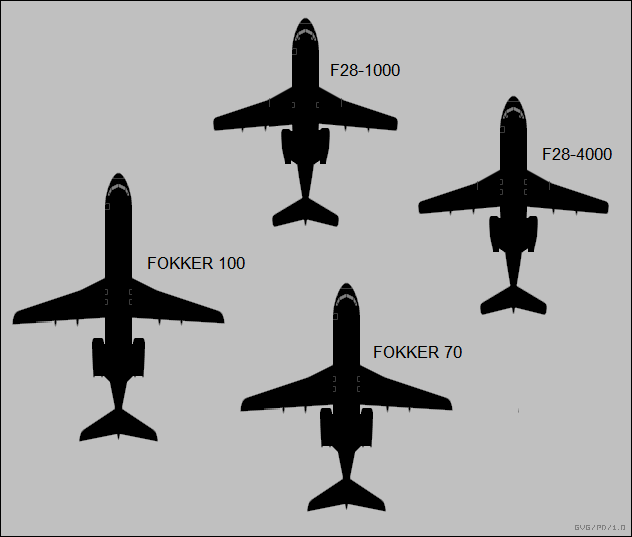

Fokker obtained backing from the Dutch and West German governments, acquiring MBB and VFW of West Germany as partners, along with Short Brothers of Belfast. Each partner was responsible for different assemblies, with final assembly in the Netherlands. The first of three prototypes of the baseline "F28-1000" performed its initial flight on 9 May 1967, with certification obtained in early 1969 and the first revenue flight on 28 March 1969.

The Fellowship ended up having much the same configuration as the BAC One-Eleven, if smaller, the F28 being a low-wing aircraft made mostly of aircraft aluminum alloy with tricycle landing gear, swept flight surfaces and a tee tail, with engines in nacelles on each side of the tail. It was powered by two Rolls-Royce RB.183-2 Spey Junior Mark 555-15 turbofans with 43.8 kN (4,465 kgp / 9,850 lbf) thrust each. There was an AiResearch APU behind the rear bulkhead for engine starting and ground power.

The wings had a slight "crescent" leading edge, with a strong sweep for the inboard third of the wingspan and a shallower sweep outboard, with a wing fence dividing the two sections of span. The wings had a slight dihedral, each featuring an aileron outboard, double slatted Fowler flaps in three segments over the inboard 70% of the wing, and five spoilers acting as "lift dumpers". The spoilers were not used in flight, instead being used as landing airbrakes, Fokker engineers seeing that as simpler and more reliable than thrust reversers, and also reducing the chance of engine foreign object ingestion. Strong brakes were fitted to the landing gear to help reduce landing roll as well.

The tailcone was split and could be extended to each side to act as a variable airbrake. The wings were de-iced by engine bleed air. Tail flight surfaces were conventional, rudder and elevators, though the tailplane was variable-incidence. The tailfin had a prominent forward fillet.

___________________________________________________________________

FOKKER F28 FELLOWSHIP:

___________________________________________________________________

wingspan:

23.58 meters (77 feet 4 inches)

wing area:

76.4 sq_meters (822 sq_feet)

length:

27.4 meters (89 feet 11 inches)

height:

8.47 meters (27 feet 10 inches)

empty weight:

13,975 kilograms (30,805 pounds)

MTO weight:

28,125 kilograms (62,000 pounds)

max speed at altitude:

880 KPH (550 MPH / 475 KT)

max cruise height:

10,670 meters (35,400 feet)

range:

1,410 kilometers (875 MI / 760 NMI)

___________________________________________________________________

The default fuel tankage consisted of tanks in the wings, with a total capacity of 9,740 liters (2,570 US gallons); tanks could be optionally fitted in the wing center section to provide an additional 3,300 liters (871 US gallons) of fuel. All gear assemblies had twin wheels, the main gear pivoting from the wings to retract into the fuselage, the steerable nose gear retracting forward. Low-pressure tires could be ordered as an option for rough field operations.

There were two flight crew, not counting a flight attendant. Avionics included radios, radio navigation and landing aids, identification transponder, autopilot, and weather radar, the exact elements being dependent on customer specification. The cockpit featured distinctive "eyebrow" windows. The F28 had only single-class accommodations, with from 55 to 65 seats in a five-across format, the number varying as per seat pitch; as with the BAC One-Eleven, the windows were of oval configuration. There was a galley forward, with a toilet, cloakroom, and luggage compartment in the rear. There was an airstair door on the forward left fuselage, with a service door matching it on the right, plus an emergency exit over each wing. There was a baggage hold under the floor fore and aft of the wing, with the doors on the right side of the fuselage. Follow-on variants included:

The F28-4000 led to the "F28-6000", with wider wings, leading-edge slats, and new Spey Junior RB.183 Mark 555-1H engines for better short-field performance as well as quieter operation, but only two were built, and they were reconverted to F28-2000s when sold. A similarly improved F28-3000, the "F28-5000", never flew. Although there were discussions with Fairchild-Hiller of the US to build the F28 under license as the "FH.228" -- Fairchild-Hiller having built the F27 as the "FH.227" -- which would have featured more modern engines, nothing came of the exercise.

By the time the last Fellowships were rolled out in 1987, 241 machines had been built. Along with commercial users, the F28 was flown as a transport by the military services of several nations, including Argentina, Colombia, Ghana, Indonesia, the Philippines, and Togo, with Tanzania using one for its flight agency. The F28 is now almost completely out of service.

BACK_TO_TOP* The production of the F28 Fellowship was ended to make way for a successor, announced in 1983 -- with original concepts being named the "F28 Mark 0100", "Super F28", and "F.29", but which would emerge as the "Fokker 100". It was basically a stretched and rethought F28, with a redesigned wing, new-generation Rolls-Royce Tay turbofans, and a Rockwell-Collins CRT-based glass cockpit. Two prototypes were built, the first performing its initial flight on 30 November 1986, the second following on 25 February 1987. Certification was awarded in November 1987, with first deliveries -- to Swissair -- in early 1988, after some troublesome production delays.

The general configuration of the Fokker 100 was the same as that of the F28; but along with being longer, the Fokker 100 deleted the cockpit "eyebrow" windows above the windscreens. Another noticeable difference was the prominent exhaust for the APU on the right side of the tail. The baseline model used Tay 620-15 engines with 61.6 kN (6,280 kgp / 13,850 lbf) thrust each; some customers ordered uprated Tay 650-15 engines instead, with 67.2 kN (6,800 kgp / 15,000 lbf) thrust each. The Tay engines were fitted with clamshell thrust reversers.

___________________________________________________________________

FOKKER 100:

___________________________________________________________________

wingspan:

28.08 meters (92 feet 1 inch)

wing area:

93.5 sq_meters (1,006.4 sq_feet)

length:

35.53 meters (116 feet 7 inches)

height:

8.5 meters (27 feet 10 inches)

empty weight:

24,375 kilograms (53,740 pounds)

MTO weight:

43,090 kilograms (95,000 pounds)

max speed at altitude:

835 KPH (520 MPH / 450 KT)

max cruise height:

10,670 meters (35,000 feet)

range:

2,485 kilometers (1,545 MI / 1,340 NMI)

___________________________________________________________________

Maximum passenger capacity in an all-economy configuration was 122 seats, though 107 seats were more conventional, with seating in a five-across configuration; a mixed-class arrangement might consist of 12 seats, four across, in a forward section, plus 85 seats, five across, in the rear. There were forward and aft galleys and toilets. As with the F28, there was an airstair door forward on the left, with a matching service door on the right, along with an optional service door on the rear. There were two emergency exits over each wing.

An extended-range variant, with additional fuel tanks in the wings, was introduced in 1993. In that same year, a "shrunk" Fokker 100 was introduced to replace the F28, this machine being designated the "Fokker 70", replacing the F.28-4000, with the fuselage length cut down by 4.7 meters (15 feet 4 inches) -- for a total length of 30.91 meters (101 feet 4 inches), with empty weight reduced by about 6% -- and capacity reduced to 79 seats. The Fokker 70 was powered by twin Rolls-Royce Tay 620 turbofans, with 61.6 kN (6,280 kgp / 13,850 lbf) thrust each. Initial flight of the Fokker 70 was on 1 April 1993, with certification and customer deliveries in 1994.

Fokker went bankrupt in 1996, with the last aircraft produced by the firm rolled out in 1997. 280 Fokker 100s and 48 Fokker 70s had been built to that time, with the total number of Fokker jetliners amounting to a respectable sum of 241 + 280 + 48 == 569 aircraft. There had been consideration of a quick-change "combi" passenger-freighter variant, the "Fokker 100QC" and a further stretched "Fokker 130", but neither happened.

However, there were aftermarket executive jet conversions of the Fokker 100 as the "Fokker 100EJ". One used Fokker 100 was also obtained for trials in 2013 by the French Defense Ministry's "Direction Generale de l'Armement (DGA / General Directorate for Armament)", being fitted with the nose of a Dassault Rafale fighter for radar tests, and also carrying Rafale external equipment pods for evaluation. It was apparently even fitted with Mica air-to-air missiles -- most improbable kit for a jetliner.

Attempts to find new owners to restart production went nowhere; Fokker's assets were sold off, with the Fokker name now enduring as an element of the Stork BV firm, the Fokker component working on aircraft assemblies. Fokker 100s and 70s still linger in commercial service, though they are fading out.

A Dutch company named "Fokker Next Gen NV" -- originally "Rekkof Restart", "Rekkof" being "Fokker" spelled backwards -- has been pushing various updates of the Fokker 70 and 100 for decades, the current concept being the "Fokker Next Gen", powered by liquid hydrogen. If it happens, it won't be right away.

BACK_TO_TOP* The BAC One-Eleven and the Fokker Fellowship series made a profit, though they never really amounted to major rivals to the DC-9 and the 737. Two other European forays into the jetliner business in that timeframe were simply disasters.

The first, the "VFW 614", had its roots in a concept devised in the early 1960s by the West German Entwicklungsring Nord (ERNO) group, consisting of Focke-Wulf, Hamburger Flugzeugbau, and Weser. The jetliner, the "E.614", was to have 36 to 40 seats and be powered by twin Lycoming PLF1B-2 turbofans. A reshuffling of the West German aircraft industry followed, with players consolidated as the Flugtechnische Werke (VFW) of Bremen. VFW continued work on the E.614, recast as the VFW 614.

Lycoming gave up on the PLF1, with the VFW 614 powerplant then being changed to the Rolls-Royce/SNECMA M45H turbofan, being developed specifically for the VFW 614. In 1968, the VFW 614 program was given the green light by the West German government, which provided 80% of the funding; full-scale production was authorized in 1970. By that time, VFW had joined up with Fokker -- officially, the machine was the "VFW-Fokker 614", at least for a time, the arrangement proving unsatisfactory and temporary. Risk-sharing partners were found at other European aviation firms for the project.

The first of three prototypes of the VFW 614 performed its initial flight on 14 July 1971. It was a low-wing aircraft with swept flight surfaces, a blunt nose, and tricycle landing gear. Very unconventionally, the twin M45H turbofans were mounted on pylons on top of the wings. This reduced airframe weight as compared to tail-mounted engines, and also reduced risk of foreign-object ingestion, permitting use of a short and robust undercarriage, all gear assemblies having twin wheels, suitable for rough-field operation. The aircraft had good short-field capability. Wingspan was 21.5 meters (70 feet 6 inches), length was 20.57 meters (67 feet 6 inches), and empty weight was 11,000 kilograms (24,250 pounds).

The development program did not go well, Rolls-Royce's bankruptcy causing particular anxiety over the supply of engines. To compound the problems, the first prototype was lost in an accident on 1 February 1972. Orders were hardly flooding in, but the first production machine was still rolled out in 1975. The VFW 614 didn't sell; it was expensive, there were apparently some reliability problems, and it simply looked awkward, it didn't look like a finished product. 21 were built in all, including the three flight prototypes, and two of them were never flown; three others, not included in the production total, were scrapped before completion. The program was given the axe in 1977.

Three production machines were obtained by the Luftwaffe, the German air force, while the rest were obtained by three European regional airlines. The commercial service life of the VFW 614 was short, with VFW buying back the airframes from commercial operators in 1981, it seems just to get rid of the support liability. The Luftwaffe machines remained in service to 1999, while one machine was operated by the German aerospace agency, the DLR, for technology trials up to 2012. Incidentally, although the VFW 614 did help discourage acceptance of the topside-mounted engine configuration, that wasn't really one of the design's problems, and that configuration has been recycled in the 21st century with the Japanese Honda HondaJet small executive jet.

* While the VFW 614 was working its way through its sad history, in 1967 the French Dassault firm decided to try to compete head-on with the Boeing 737, developing a similar jetliner but with 140 seats, outsizing the 115-seat Boeing 737-200. The French government provided backing. The new jetliner was given the name "Mercure (Mercury)", after the fleet-footed classical deity. A full-scale mockup was publicly displayed in 1969 at the Paris Air Show, with the initial prototype of the "Mercure 100" rolled out in April 1971, its initial flight following on 28 May 1971.

The Mercure looked so much like a 737 that even someone familiar with aircraft might confuse the two. Like the 737, the Mercure was a low-wing aircraft with all-swept flight surfaces, and a turbojet engine under each wing -- the Pratt & Whitney JT8D-11, with 66.7 kN (6,800 kgp / 15,000 lbf) thrust. The Mercure's wingspan was 30.55 meters (100 feet 3 inches), length was 34 meters (111 feet 6 inches), and empty weight was 24,450 kilograms (56,060 pounds). A second prototype, with the JT8D-15 engines projected for production, flew for the first time on 7 September 1972.

There were high hopes for the Mercure, but orders were slow to materialize. On the basis of an order for ten machines from the French Air Inter airline, Dassault committed to production. The first production machine performed its maiden flight on 19 July 1973, with certification and first delivery in early 1974. No other orders came in, and the ten Air Inter machines were the only production aircraft built; one of the prototypes was brought up to production spec and sold to Air Inter as well. Dassault tried to drum up interest in an improved "Mercure 200C" in hopes of saving the program, but nobody bought off on it.

The last Mercure was delivered in late 1975, and that was the end of the matter. Not only had the French government invested heavily in the program, it also ended up subsidizing Air Inter operations with the type. The last flight of a Mercure was in 1995; one survives in a German air museum. The Mercure ended up being one of the biggest humiliations of the European aircraft industry in the postwar period.

* The fall of the Mercure program left Boeing unchallenged as the giant of the jetliner market, with Boeing officials finding humor in the flailings of the Mercure; they hardly noticed the VFW 614. Even the relatively successful BAC One-Eleven and Fokker Fellowship had not threatened Boeing dominance. However, as the Mercure program fell to earth, the Europeans, having absorbed painful lessons, were regrouping under the Airbus consortium -- developing the Airbus A300, which performed its first flight in 1972.

Boeing officials publicly derided the A300 as likely to go the way of the Mercure. Although the A300 did get off to a slow start, in their contemptuous judgement they turned out to be very much mistaken -- finding out the hard way that Boeing had now acquired stiff global competition, leading to an enduring industrial rivalry never exceeded for bitterness.

BACK_TO_TOP* Sources include:

Various editions of JANE'S ALL THE WORLD'S AIRCRAFT were consulted as well, with the online Wikipedia providing hints and links to various websites.

* Revision history:

v1.0.0 / 01 jan 14 v1.0.1 / 01 dec 15 / Review & polish. v1.0.2 / 01 nov 17 / Review & polish. v1.0.3 / 01 oct 19 / Review & polish. v1.0.4 / 01 aug 21 / Review & polish. v1.0.5 / 01 jul 23 / Review & polish. v1.0.6 / 01 jul 25 / Review & polish.BACK_TO_TOP