* The P-47 grew out of a series of fighter aircraft developed by the Seversky company during the 1930s, with a number of early developments leading to the "P-35" and to the "P-43" -- with the P-43 design being the basis for the bigger and more powerful Thunderbolt.

* The P-47 Thunderbolt was, in a very indirect sense, a gift from Russia to the United States. The aircraft was the product of two Russian immigrants, Alexander De Seversky and Alexander Kartveli, who had left their homeland to escape the Reds.

Seversky was a colorful character, born in 1894 in Russian Georgia, and flying as a naval aviator in the Tsar's forces in World War I. He lost a leg early in the conflict, but returned to the air with an artificial leg and claimed 13 "kills" in combat. In 1918, after the October Revolution of 1917, Seversky was sent to the US as part of a military mission. Having no confidence in the new regime, he decided to stay in America, and became an aeronautical engineer in employ of the US Army Air Corps, where he worked closely with air warfare pioneer General Billy Mitchell. Seversky obtained American citizenship in 1927.

In 1931, Seversky founded the "Seversky Aircraft Company" at Farmingdale on Long Island, in New York state. The company was very small, with Seversky acting as president, designer, and chief test pilot, but he also hired a fellow Russian expatriate named Alexander Kartveli as a design engineer. "Sasha" Kartveli had been a Tsarist artillery officer and had even been a circus trapeze artist for a time. He was an original designer with many innovative ideas, and would eventually become chief designer when Seversky became more preoccupied with the business aspects of running the company.

* The first Seversky design was the "SEV-3" amphibian. The SEV-3 was an all-metal, low wing monoplane that was powered by a Wright J-6 air-cooled radial engine providing 200 kW (420 HP), and had an interesting arrangement of retractable floats that allowed it to land on water or a runway. The rear edges of all flight surfaces were in the form of elliptical curves, a feature that would be retained in its descendants. The "3" in the SEV-3 designation indicated that it was a three-seat aircraft. It was intended for commercial use. First flight of the SEV-3 was in June 1933, with six production aircraft built. It was fast for its time, and in October 1933, Seversky set an international speed record of 290 KPH (180 MPH) with the prototype, which had been fitted with an uprated engine.

In 1934, the SEV-3 design was modified into a trainer configuration, designated the "SEV-3XAR". The float system was replaced by fixed landing gear with spats, the canopy was redesigned, and the engine was changed to a Wright R-975 radial with 710 kW (950 HP). The SEV-3XAR was entered in an Air Corps competition for a flight trainer, and the Army ordered thirty examples of a derivative, the "BT-8 (Basic Trainer 8)". Unfortunately, Air Corps regulations required that the engine of a trainer be limited to 300 kW (400 HP), and so the BT-8 was powered by a Pratt & Whitney (P&W) R-985-11 radial with that power rating. That left the aircraft seriously underpowered, making it a danger to inexperienced pilots, and it was quickly replaced by the North American "BT-9", which evolved into the famous "AT-6 Texan" trainer.

* Although the BT-8 was a loser, Kartveli had also designed a fighter derivative of the SEV-3, initially designated "SEV-2M" but quickly redesignated "SEV-2XP", where the "2" indicated a two-seat aircraft. The SEV-2XP used a Wright R-1670 14-cylinder air-cooled radial engine with 550 kW (735 HP). It had fixed landing gear with spats, and was armed with one 7.62-millimeter (0.30-caliber) and one 12.7-millimeter (0.50-caliber) M2 Browning machine gun firing through the propeller arc, plus a 7.62-millimeter Browning on a rearward-facing hand-held mount for use by the back-seater.

In May 1935, the Air Corps announced a competition for a new single-seat fighter. Seversky believed the SEV-2XP could win, even though it was a two-seat fighter, and entered it in the competition. However, the SEV-2XP was damaged in mid-June while flying to Wright Field in Ohio for the fly-off, and the machine went back to the shop. Second thoughts arose about the aircraft's configuration, and so it was reworked into a single-seat fighter designated the "SEV-1XP". Along with the new single-seat cockpit and the elimination of the flexible gun, the fixed landing gear was changed to gear that retracted into underwing fairings. The Wright R-1670 had not been powerful enough, and so, after experiments with different engine fits, the Seversky Company installed a P&W R-1830-9 Twin Wasp radial, with 635 kW (850 HP).

The Seversky Company was able to make these changes because the Air Corps postponed the fighter competition, with the fly-off rescheduled to March 1936. The SEV-1XP was entered in the competition, and ended up as a finalist against the Curtiss "Model 75 Hawk". The SEV-1XP was selected as the winner of the competition on 16 June 1936, and a production order for 77 of the aircraft, with the Air Corps designation "P-35", was confirmed in early 1937. However, as tensions rose in Europe, the Air Corps also ordered 210 Hawks under the designation "P-36".

* The P-35, which had the company designation "AP-1 (Army Pursuit 1)", entered service in 1937, the last of the batch being delivered in August 1938. 76 P-35s were actually built instead of the 77 ordered, with the 77th aircraft finished as an experimental variant for the Air Corps, featuring a P&W R-1830-9 engine with a two-stage, two-speed supercharger and 895 kW (1,200 HP); better streamlining, including fully retractable landing gear; and the designation of "XP-41".

The production P-35 differed from the SEV-1XP by featuring partial mainwheel fairings instead of full fairings, seven degrees of dihedral to the outer wing panels, and a more aerodynamic front canopy.

___________________________________________________________________

SEVERSKY P-35:

___________________________________________________________________

wingspan:

11 meters (36 feet)

wing area:

20.44 sq_meters (220 sq_feet)

length:

7.67 meters (25 feet 2 inches)

height:

2.77 meters (9 feet 1 inch)

empty weight:

1,960 kilograms (4,315 pounds)

normal loaded weight:

2,540 kilograms (5,600 pounds)

max speed at altitude:

454 KPH (282 MPH / 245 KT)

service ceiling:

9,325 meters (30,600 feet)

range:

1,850 kilometers (1,150 MI / 1,000 NMI)

___________________________________________________________________

The P-35's performance was poor even by contemporary standards and its handling was atrocious, with a nasty tendency to go into a spin in a tight turn. Although Air Corps fliers appreciated the P-35's ruggedness, the aircraft was already obsolescent by the time deliveries were finished.

* Kartveli continued to refine the P-35 design while the aircraft was being produced. The company constructed a range of one-off variants with different powerplants and enhancements, with the designations "AP-2", "AP-7", "AP-4" (which flew after the AP-7), "AP-9", and the previously mentioned XP-41; and actually built a carrier-based fighter designated the "NF-1 (Naval Fighter 1)".

None of these variants went into production and are of little interest, but the AP-4 proved significant in the further development of Seversky aircraft. It featured fully retractable landing gear, flush riveting, and most significantly a P&W R-1830-SC2G engine with a belly-mounted turbocharger, providing 895 kW (1,200 HP) and good high-altitude performance. Exhaust-driven turbocharger technology had been refined by Boeing as part of the development program for the B-17 bomber; the opportunities offered by it for improved performance were of great interest to other aircraft manufacturers.

The one AP-4 built was used as a test platform to evaluate means of improving the aerodynamics of radial-engine fighters. It was fitted with a very large prop spinner and a tight-fitting engine cowling, following similar experiments that had been performed with the first production P-35. The AP-4's big spinner was later removed and a new tight-fitting cowling was installed. Unsurprisingly, these measures led to engine overheating problems. On 22 March 1939, the engine caught fire in flight, the pilot had to bail out, and the AP-4 was lost. However, the AP-4 would lead to bigger and better things.

* Incidentally, Seversky also built a refinement of the original two-seat fighter concept embodied by the SEV-2XP, resulting in the "SEV-2PA Guardian", apparently also referred to as the "X-BT", which was available with retractable landing gear or floats. The USSR bought one with each landing gear option, plus a manufacturing license, but never put the type into production.

The Imperial Japanese Navy actually bought 20 SEV-2PAs, apparently through a "front" operation to conceal the ultimate customer, but found them disappointing. Two of them were passed on to the ASAHI SHIMBUN newspaper as hacks. Sweden ordered 52 SEV-2PAs as dive-bombers, but only two were delivered before the US embargoed exports of fighters to Sweden in October 1940. The other 50 ended up in Air Corps hands as the "AT-12" and were used as gunnery trainers.

* In addition, the Seversky Company sold Sweden a refinement of the P-35 designated the "EP-1 (Export Pursuit 1)". The EP-1 was powered by a P&W R-1830-S1C1 Twin Wasp engine with 745 kW (1,000 HP), improving its performance relative to the P-35 by over 40 KPH (25 MPH). The Swedes ordered a total of 120 EP-1s, with an initial order placed in mid-1939.

Only 60 of these aircraft were actually delivered to Sweden. They were armed with two 7.9-millimeter guns in the nose and one 13.2-millimeter gun in each wing, for a total of four guns. They served with the Swedish air force through the war, and occasionally escorted intruding Allied bombers into internment -- though they could barely keep up and were at substantial risk of being shot at, since the EP-1 looked quite a bit like a German Focke-Wulf FW 190 fighter from some angles.

Following the embargo against Sweden, the other 60 EP-1s were taken over by the Air Corps with the designation of "P-35A". They were apparently fitted with two 12.7-millimeter Brownings in the cowling and a 7.62-millimeter Browning in each wing. 48 were sent to the Philippines, where they fought in the futile defense of the islands in December 1941 and January 1942, but they were hopelessly outclassed by Japanese fighters. The other P-35As were used as Air Corps trainers.

BACK_TO_TOP* On 13 October 1939, the Seversky Aircraft Company changed its name to the "Republic Aviation Company" after the stockholders bought out Seversky's holdings in the company. The firm's efforts to that time had done nothing that would win it a place in the history books, but that would soon change.

Although the turbocharged AP-4 demonstrator had been lost, the Air Corps liked it enough to order thirteen more in May 1939, to be designated "YP-43". However, the USAAC kept shifting requirements and the YP-43 ended up looking much different from the AP-4. The YP-43 was powered by a P&W R-1830-35 14-cylinder Twin Wasp radial engine with a turbocharger, providing 895 kW (1,200 HP) and driving a three-blade propeller. Armament consisted of two 12.7-millimeter Brownings in the nose, plus a single 7.62-millimeter Browning in each wing. The cockpit scheme was revised, leading to a distinctive "razorback" configuration.

* The first of the thirteen YP-43s was delivered in September 1940, and the last was delivered in April 1941. In the meantime, Republic had been working on a new version of the YP-43 with a more powerful engine, to be named the "XP-44 Rocket", as well as on a fighter designated the "AP-10" that was a considerable departure for Republic Aviation. The AP-10 was to be a lightweight fighter, powered by an Allison V-1710 water-cooled inline engine and armed with a pair of 12.7-millimeter Brownings. The Army backed the project and ordered two prototypes in November 1940 in somewhat different configurations as the "XP-47" and "XP-47A".

However, by that time the war in Europe was in high gear, and Air Corps brass decided that the company's current fighter concepts weren't good enough to deal with contemporary German fighters. Alexander Kartveli went back to the drawing board and came up with what looked like a much bigger and badder version of the YP-43; the Air Corps decided they liked it and ordered a prototype, to be designated "XP-47B". The XP-47A, which had little or nothing in common with the new design, was abandoned.

Air Corps generals must have swallowed hard when they saw the design for the XP-47B for the first time: it was a monster. Kartveli is said to have remarked: "It will be a dinosaur, but it will be a dinosaur with good proportions." Empty weight was 4,490 kilograms (9,900 pounds), or 65% more than the YP-43. The new aircraft was to be powered by a P&W R-2800 Double Wasp 18-cylinder two-row radial engine with 1,490 kW (2,000 HP), linked to a hefty system of ductwork leading back to a turbocharger inside the rear fuselage. Armament was to be eight 12.7-millimeter Brownings, with four in each wing.

* The Air Corps decided to focus on the XP-47B, and so the XP-44 Rocket was abandoned along with the XP-47A. However, the new fighter wouldn't go into production for some time, so to keep Republic's production lines in operation the Air Corps ordered 54 production P-43s. Delays occurred in the XP-47B program, and so the Air Corps ordered another batch of 80 "P-43As", with a slightly different engine fit. Further delays led to yet another order for 125 "P-43A-1s" intended as Lend-Lease aircraft for China, with this last batch featuring armament of four 12.7-millimeter Brownings, plus self-sealing fuel tanks.

___________________________________________________________________

REPUBLIC P-43A LANCER:

___________________________________________________________________

wingspan:

11 meters (36 feet)

wing area:

20.81 sq_meters (224 sq_feet)

length:

8.67 meters (28 feet 6 inches)

height:

4.27 meters (14 feet)

empty weight:

2,600 kilograms (5,730 pounds)

loaded weight:

3,540 kilograms (7,800 pounds)

max speed at altitude:

575 KPH (355 MPH / 310 KT)

service ceiling:

26,000 meters (26,000 feet)

range:

1,290 kilometers (800 MI / 695 NMI)

___________________________________________________________________

Including the thirteen YP-43As, a total of 272 P-43s of all types was delivered by the time of the last delivery in March 1942. The ultimate fate of all these aircraft is a bit fuzzy, mostly because the "Lancer", as it was known, was so forgettable. At least 51 did make it to China and some served with Claire Chennault's American Volunteer Group, the "Flying Tigers", but the turbocharger and the self-sealing tanks proved unreliable. The Lancer, in short, was a dog.

Most of the rest were converted into photo-reconnaissance aircraft, and a handful of these photo-reconnaissance Lancers were provided to Australia. These aircraft appear to have been given designations such as "P-43B", "P-43C", and "P-43D", with all then redesignated "RP-43" (where the "R" stood for "restricted from combat") in the fall of 1942, but the details are both unclear and uninteresting. The type saw little combat in any capacity. The P-43's only real significance was as a stepping stone to something better, and a way of keeping Republic's production lines going until they could deliver the new XP-47B.

* The XP-47B first flew on 6 May 1941, with test pilot Lowry P. Brabham at the controls. Although there were minor problems, such as a slight amount of cockpit smoke that turned out to be due to an oil drip, the aircraft proved impressive in its first trials.

The XP-47B was essentially built around the big Twin Wasp engine and its turbocharger. The loss of the AP-4 put an end to Kartveli's experiments with tight-fitting cowlings, so the engine was placed in a broad cowling that opened at the front in a "horse collar" shaped ellipse. The cowling admitted air for the engine, left and right oil coolers, and the turbocharger intercooler system.

The engine's exhausts were routed into a pair of pipes that ran along each side of the cockpit to drive the turbocharger turbine, which sat in the bottom of the fuselage about halfway between cockpit and tail. At full power, the pipes glowed red at their forward ends. A "waste gate" shutter either vented the exhaust gas directly to the surrounding atmosphere, or, at higher altitudes, drove it through the turbocharger turbine, spinning it at 60,000 RPM. The turbocharger's intake was fed by ducting at the bottom of the fuselage leading to the front of the aircraft, with the ducting run through an "intercooler" that dumped waste heat into the airflow to increase power.

The complicated turbocharger scheme with its ductwork gave the XP-47B a deep fuselage, and the wings had to be mounted at a relatively high position. That was a problem, since to take advantage of the powerful R-2800 engine, the aircraft was fitted with a huge four-bladed, electrically-operated, constant-speed Curtiss propeller with a span of 3.17 meters (12 feet 2 inches). That meant that the XP-47B needed long landing gear to ensure adequate prop clearance on the ground, but long landing gear had to be very rugged and heavy, and also took up excessive space in the wing. Since Kartveli wanted to put the aircraft's guns in the wings outboard of the landing gear, the main landing gear featured a remarkable scheme by which they telescoped out 23 centimeters (9 inches) as they were extended.

There were four 12.7-millimeter Browning machine guns in each wing, with the positions of the guns staggered to allow feed from ammunition boxes set side by side in the outer sections of the wings. Each ammunition box had a maximum capacity of 350 pounds of ammunition. Main and auxiliary self-sealing fuel tanks were placed under the cockpit, providing a total fuel capacity of 1,155 liters (305 US gallons). That was a large fuel capacity for the time, but it would still prove inadequate.

The cockpit was roomy by the standards of the era, as might be hoped for such a big machine, and the pilot's seat was comfortable, "like a lounge chair" as one pilot would later put it. The pilot was provided with every convenience, including cabin air conditioning. The prototype featured a car-style door to get in and out, though it would be quickly abandoned in production machines in favor of a canopy that slid back over the aircraft's spine. The aircraft was of all-metal construction, except for fabric-covered tail control surfaces. The fabric-covered control surfaces would prove troublesome.

BACK_TO_TOP* The XP-47B gave the US Army Air Forces (USAAF, which had superseded Air Corps in June 1941) cause for both optimism and apprehension. Aircraft performance and firepower appeared to be everything asked for, but the XP-47B was something very new, and as a result it had its share of teething problems.

The sheer size and power of the aircraft made it a handful. The XP-47B was also an "earth lover", demanding a lot of runway to get into the air. This would not only be true for every other P-47 ever built, but also with Kartveli's later jet designs. There were problems with canopies that jammed, with the guns, with the fuel system, with the engine installation. At high altitudes the ignition system arced and the loads on the control surfaces became unacceptable, the ailerons locking up. The fabric-covered control surfaces also tended to "pop" at high altitudes from the expansion of air trapped in them.

Republic addressed the problems, coming up with a sliding canopy that could be discarded in an emergency, a pressurized ignition system, and new all-metal control surfaces. While the engineers worked frantically to get their "dinosaur" to fly right, USAAF brass had to think hard and ask themselves if they really wanted the P-47.

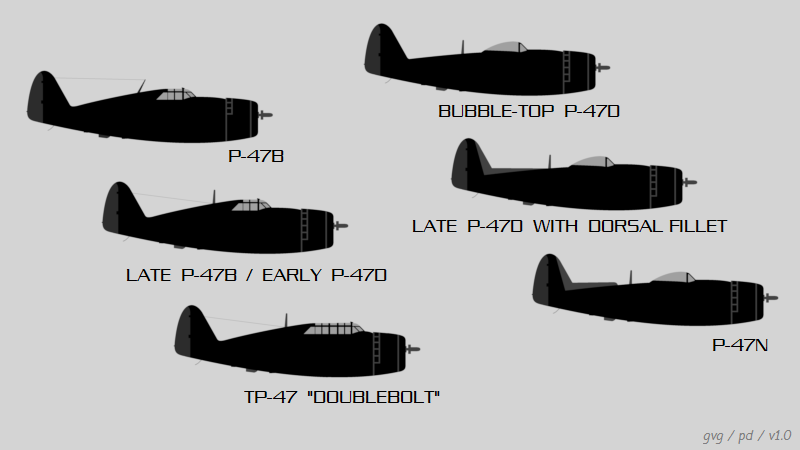

The answer was YES, and the USAAF ordered 171 production "P-47Bs". An engineering prototype P-47B was delivered in December 1941, with a production prototype following in March 1942, and the first actual production model delivered in May. Republic continued to tweak the design as more P-47Bs were produced, adding the sliding canopy, a new General Electric (GE) turbocharger regulator for the R-2800-21 engine, and (eventually) all-metal control surfaces. The radio mast behind the cockpit was slanted forward to maintain the aerial wire length with the new sliding canopy, providing a recognition feature for this variant.

The aircraft now had a name: "Thunderbolt". In postwar sources it would acquire the nickname of "Jug", said to be due to its resemblance to a jug of booze; as a contraction of "juggernaut"; or in reference to a "thunderjug", meaning a chamberpot. However, some sources claim this nickname was not in common use during the war, that the only nicknames it had during the conflict were "Bolt" or "T-Bolt". The matter of nicknames might as well be ignored, since it is very confusing, and an example of how historical studies sometimes seem to only muddy the facts.

* Initial deliveries of the Thunderbolt to the USAAF were to the 56th Fighter Group (FG), which was also on Long Island. The 56th served as an operational evaluation unit for the new fighter.

Teething problems continued. A Republic test pilot was killed in an early production P-47B when it went out of control in a dive, and there were many crackups with other early P-47Bs, including crashes that occurred when the tail assembly fell off. The original XP-47B was lost in August 1942 when it caught in fire in flight, forcing the pilot to bail out.

Production changes gradually addressed the problems, and on the balance, with experience the USAAF decided that the P-47 was worthwhile, quickly following the initial order for P-47Bs for 602 more examples of a refined type, the "P-47C", with the first of the variant delivered in September 1942. The initial P-47Cs were very similar to the P-47B, but had strengthened all-metal control surfaces, a stronger tail, a short vertical radio mast, and other tweaky changes.

After the initial manufacture of a block of 57 P-47Cs, production moved to the "P-47C-1", which had a 20-centimeter (8-inch) fuselage extension forward of the cockpit. This corrected center of gravity problems and improved service access to the engine. There were a number of other minor changes. 55 P-47C-1s were built, to be followed by 128 "P-47C-2s", which were identical except for a belly attachment point for either a 225-kilogram (500-pound) bomb or, more generally, a 758-liter (200 US gallon) conformal belly ferry tank. The P-47C-2 was really the first combat-ready Thunderbolt.

The main production P-47C subvariant was the "P-47C-5", featuring a whip antenna replacing the mast antenna, plus cockpit heating and other small changes. 362 were built. The P-47C-2 and P-47C-5 were the first Thunderbolts to be sent overseas for combat operations.

* The P-47B not only led to the P-47C, but to a few other "one-off" variants. A single reconnaissance machine designated the "RP-47B" was modified from a P-47B. The 171st and last P-47B was also used as an evaluation platform under the designation "XP-47E" to test the uprated R-2800-59 engine, a pressurized cockpit, and eventually a new Hamilton Standard propeller. Another P-47B was later fitted with new "laminar flow" wings in a search for higher performance and redesignated "XP-47F", but nothing came of this experiment.

BACK_TO_TOP